Bioclear earth puts its expertise to use in optimizing biogas production in the European innovation project MICRO4BIOGAS

Alongside solar and wind energy, biogas is an important step in the energy transition.There are approximately 18,000 biogas installations in Europe, which account for half of the global biogas production.

A favourable aspect of biogas is that its production is robust and does not depend on weather conditions. In addition, biogas is a so-called energy carrier, which means that it can be stored for later use, for example as a fuel. Another advantage of biogas production is that the energy is produced from waste streams. Furthermore, optimal biogas production ensures that no methane is released into the atmosphere and remaining residual flows (digestate) are used as soil improver and fertiliser. In this way the cycle with the soil is closed. In addition, the use of biogas is CO2-neutral.

The wonderful world of biogas production

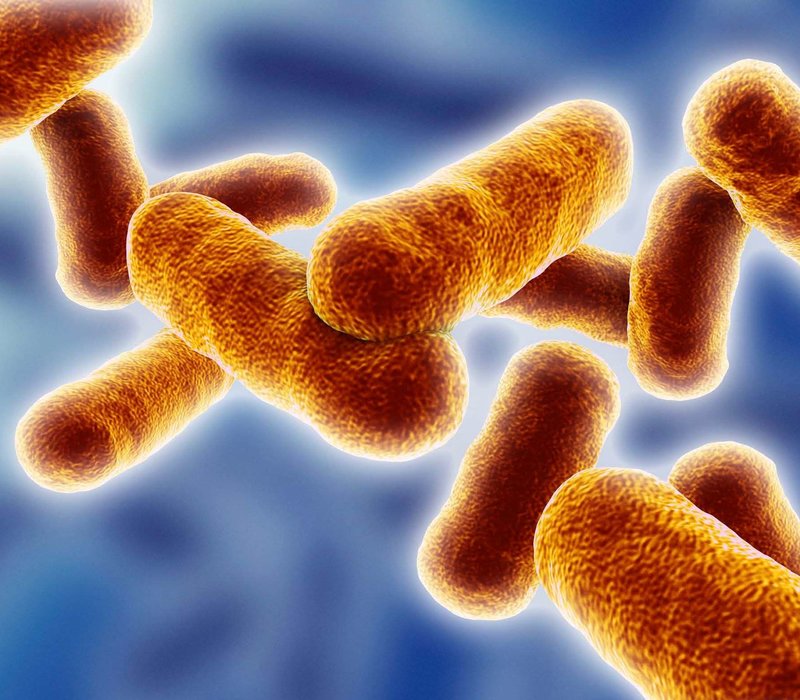

The production of biogas has been a black box so far. You could compare a reactor with our intestines, in which bacteria, fungi and yeasts take care of breaking down food and converting it into building blocks and energy. This process can run optimally if the right micro-organisms are present, but it can also be disturbed, for example, by eating contaminated food. Similar processes take place in a biogas reactor, but exactly which ones and how they work together is yet unclear. Because of this gap in knowledge, there is still a lot of room to optimise these processes.